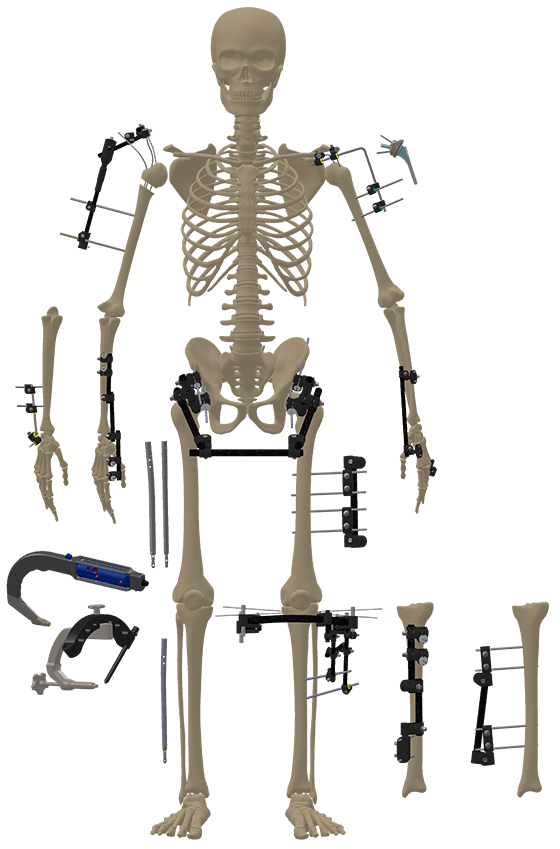

Our scope of work covers traumatology, cosmetology and orthopaedics for the entire skeleton, but also vascular surgery with the development of implants made of innovative materials.

Our skills

- Experience as a design and engineering firm

- Excellent command of conventional and innovative machining processes

- Biomechanical expertise

- Innovative materials

- Ability to analyze and represent the needs expressed by laboratories and surgeons

- Partnerships with measurement and testing laboratories

- Support with certification

- 3D design and mechanical simulation software

- Prototype creation, industrialization prior to manufacturing

Creation process

Feasibility and specifications

We run in-depth feasibility studies with our customers and cerate precise functional specifications.

Principles

We exchange views on basic diagrams with our customers until the product is validated.

Scale model 0.0

We create scale models until the functionality tests are convincing.

Prototype 0.1

A prototype compliant with the validation tests is then designed.

Tests

Some tests are processed in laboratories and on cadavers.

Pre-serie

A first pre-series is made in prior to clinical trials.

Clinical trials

Clinical trials cover a long period in order to definitely validate all the functioning principles.

Quality documentation

A quality documentation is drafted in a very specific way on all the aspects of the product and in all the necessary languages.

Launch of mass production

Once all the process steps are achieved the product is ready to be used, which we follow and make it evolve with you!

Learn about our products

JPP Management has developed many products in collaboration with doctors, surgeons, researchers and engineers.